Durable Home Selection Calculator

Your Home Durability Assessment

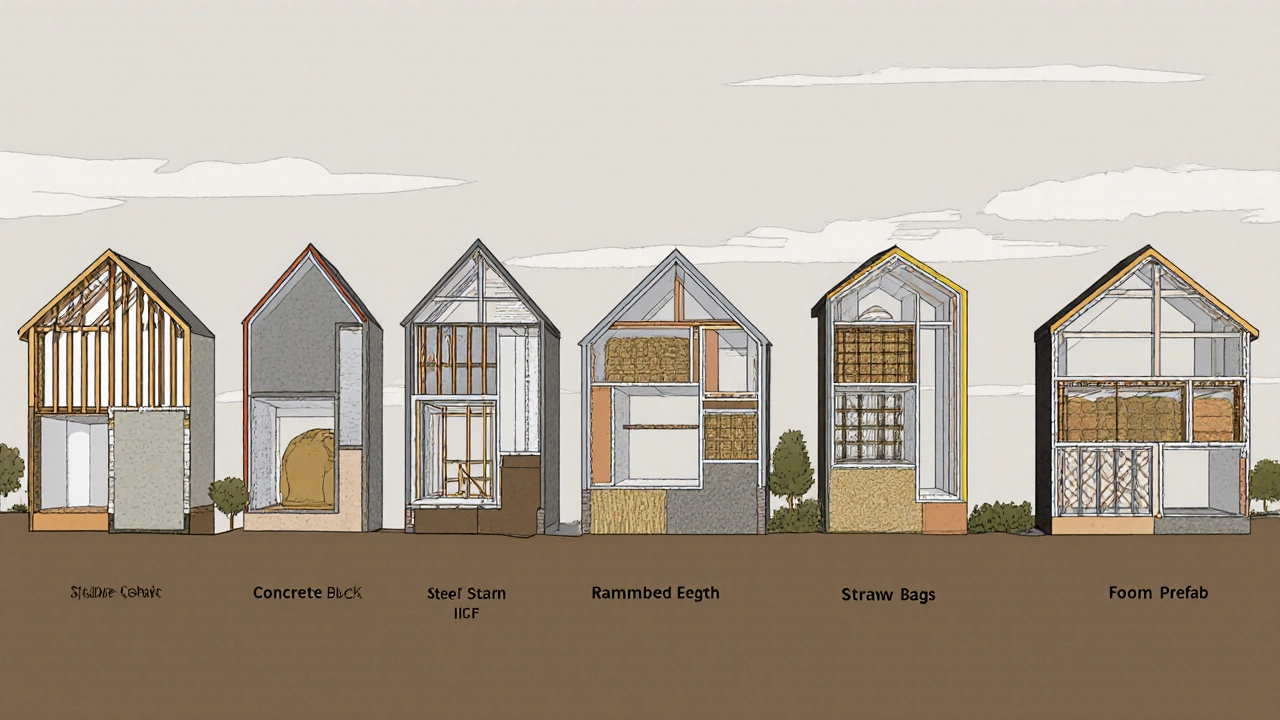

Recommended Building Systems

When you’re planning a brand‑new home, you don’t just think about style or price-you want a house that will stand up to weather, wear and time. Below we break down the construction systems that actually deliver the longest life spans, the lowest upkeep, and the best value over decades.

Key Takeaways

- Concrete‑based systems (ICF, concrete block) routinely reach 100+years with minimal repair.

- Steel framing offers excellent strength and pest resistance, but needs proper corrosion protection.

- Timber frames are economical and quick, yet require regular moisture control in damp climates.

- Earth‑based builds (rammed earth, earthbag) provide massive thermal mass and durability when properly sealed.

- Choosing the right system depends on climate, budget, and how much maintenance you’re willing to do.

What Makes a House Durable?

Durability isn’t a single trait; it’s a mix of material strength, resistance to moisture, pests, fire, and the ability to keep its shape under load. Experts gauge it by:

- Design lifespan (how many years before major structural repair is needed).

- Maintenance frequency (how often you must repaint, reseal, treat for termites, etc.).

- Environmental resilience (performance in seismic zones, high humidity, or coastal salt air).

- Energy performance (good insulation reduces wear on HVAC systems, extending their life).

With those factors in mind, let’s look at the building systems that consistently score high on durability.

Durable House Types Compared

Timber frame house is a structure built from engineered wood studs and joists, often combined with sheathing and exterior cladding. In NewZealand, it’s the most common new‑build method because of fast construction and lower material costs.

Pros: lightweight, easy to modify, good for residential design. Cons: vulnerable to rot and termites if moisture isn’t controlled; typically needs repainting every 5‑10years.

Concrete block house is a wall system made from cement‑filled masonry units, stacked and mortared to create a solid load‑bearing structure. The dense mass resists fire, wind, and pest damage.

Pros: 100+year lifespan, excellent fire rating, low maintenance. Cons: heavier foundation required, higher upfront cost.

Steel frame house is a skeleton of cold‑rolled steel studs and beams, similar to timber framing but with metal members. It’s popular for commercial builds and increasingly for high‑performance homes.

Pros: non‑combustible, termite‑proof, strong in seismic events. Cons: can rust if moisture penetrates joints; needs proper coatings and flashing.

Insulated Concrete Form (ICF) house is a system where interlocking foam blocks are stacked, then filled with concrete to create a solid, insulated wall. ICFs combine the strength of concrete with the thermal efficiency of foam.

Pros: energy‑tight, high R‑value (up to R‑22 for walls), excellent sound insulation, virtually pest‑free. Cons: higher material cost; requires skilled labor.

Rammed earth house is a wall built by compacting moist earth into formwork, resulting in a monolithic, load‑bearing mass. When sealed with a proper plaster, it can last centuries.

Pros: massive thermal inertia, low embodied energy, fire‑resistant. Cons: needs a dry climate or protective over‑cladding; longer construction time.

Earthbag house is a modular wall built from polypropylene bags filled with sand or gravel, stacked like bricks and tamped together. It’s a low‑cost, disaster‑resilient option.

Pros: excellent resistance to earthquakes and floods, cheap materials. Cons: requires waterproof plaster; aesthetics often need additional finish.

Straw‑bale house is a structure where thick bales of wheat straw are used as wall infill, then coated with plaster. It offers superb insulation.

Pros: high R‑value (up to R‑40), sustainable. Cons: moisture management is critical; not ideal for very wet climates.

Prefabricated modular house is a home whose sections are factory‑built and then assembled on site, often using steel or timber frames. Quality control is high.

Pros: fast construction, consistent quality, can integrate ICF or steel framing. Cons: transport limits size; design flexibility may be restricted.

Side‑by‑Side Comparison

| House Type | Typical Lifespan | Maintenance Frequency | Cost (NZD/m²) | R‑Value (Walls) | Best Climate |

|---|---|---|---|---|---|

| Timber Frame | 50‑80years | Every 5‑10years (paint/treated timber) | 1,800‑2,200 | R‑2.5‑R‑4 | Temperate, low humidity |

| Concrete Block | 100‑150years | Every 15‑20years (repointing) | 2,300‑2,800 | R‑3‑R‑5 (with insulation) | All climates |

| Steel Frame | 80‑120years | Every 10‑15years (coating checks) | 2,200‑2,600 | R‑3‑R‑6 (with sheath) | Coastal, seismic zones |

| ICF | 100‑200years | Low (seal checks) | 2,600‑3,200 | R‑22 (walls) | All climates, especially cold |

| Rammed Earth | 150‑300years | Low (protective coat) | 2,000‑2,500 | R‑0.5‑R‑1 (needs external insulation) | Dry, temperate |

| Earthbag | 80‑150years | Low (plaster) | 1,500‑2,000 | R‑1‑R‑2 (with external insulation) | Seismic, flood‑prone |

| Straw‑bale | 70‑120years | Medium (plaster renewal) | 1,600‑2,200 | R‑40 (walls) | Cool, dry |

| Modular Prefab | 80‑120years | Depends on core system | 2,400‑3,000 | Varies (customizable) | All climates |

How to Pick the Right System for Your Plot

Start with three questions:

- What’s the dominant weather? Coastal salt air, heavy rain, or dry winds?

- What’s your budget per square metre?

- How much ongoing upkeep are you comfortable with?

If you live in Auckland’s humid, coastal setting, a most durable house will likely need a moisture‑resistant core-either concrete block, ICF, or steel framing with proper corrosion protection. For a cheaper entry point with good longevity, earthbag combined with a breathable plaster can outlast a standard timber build, provided you keep the exterior sealed.

Don’t forget local building codes. New Zealand’s Standard NZS3604 (timber‑framed buildings) sets strict limits on how high timber structures can go in high‑wind zones. Concrete and steel have fewer height restrictions, giving you more design freedom for multi‑storey families.

Common Pitfalls and How to Avoid Them

- Ignoring moisture barriers. Even the toughest concrete will crack if water gets trapped. Install a continuous vapour‑retarder and ensure proper drainage.

- Skipping corrosion checks on steel. In salty air, regular inspection of fasteners and protective coatings prevents rust‑induced weakening.

- Under‑insulating earth‑based walls. Add an exterior rigid foam layer to keep interior humidity low and boost energy performance.

- Choosing cheapest material without lifecycle cost analysis. A low‑upfront timber price can balloon over 30years in repainting and termite treatments.

Maintenance Tips that Extend Life

Regardless of system, a few habits keep any house solid:

- Inspect roof flashings and gutter lines twice a year; water is the biggest enemy.

- Seal any cracks in concrete or masonry within weeks to stop water intrusion.

- For steel frames, touch up any scratched paint spots annually.

- Ventilate crawl spaces and basements to keep wood and earth components dry.

- Schedule a professional energy audit every 5‑7years; you’ll catch insulation gaps early.

Future‑Proofing Your Durable Home

Consider integrating passive‑solar design, rainwater harvesting, and a solar PV array. These systems don’t affect structural durability directly, but they reduce wear on mechanical components and lower long‑term operating costs-another part of the overall lifespan equation.

Frequently Asked Questions

Which house type lasts the longest?

Concrete block, ICF, and rammed earth walls can easily exceed 150years with minimal repair. ICF often tops the list because it also offers superior insulation and airtightness.

Is steel framing worth the extra cost in NewZealand?

For homes near the coast or in high seismic zones, steel’s resistance to rot, termites, and earthquakes can offset the higher material price. Proper coating keeps corrosion risk low, making it a solid long‑term investment.

Can I combine two systems, like timber frame with ICF infill?

Yes. Hybrid builds are common: a timber or steel skeleton wrapped in ICF panels provides the speed of timber construction with the durability of concrete walls. Just coordinate with structural engineers to handle load paths correctly.

How does climate affect the choice of durable house?

Humid, salty air demands moisture‑resistant cores (concrete, steel, ICF). Dry, hot areas can exploit earth‑based walls for thermal mass. In colder regions, prioritize high R‑value systems like ICF or straw‑bale with proper vapor barriers.

What’s the biggest hidden cost in durable construction?

Site preparation and proper waterproofing often get underestimated. Poor drainage can ruin even the toughest concrete or steel walls, leading to expensive repairs later.

Written by Fletcher Abernathy

View all posts by: Fletcher Abernathy