Type 5 Construction Load Capacity Calculator

Calculate the load capacity of reinforced concrete load-bearing walls for Type 5 construction based on NZS 3101 standards. This tool helps determine if your wall design meets requirements for commercial applications.

Load Capacity Result

kN/m²

Important: Type 5 construction typically requires minimum 5 kN/m² load capacity for commercial applications. The calculator uses NZS 3101 standards and accounts for safety factors of 1.5.

Note: This is a simplified calculation for educational purposes. For actual construction projects, consult a structural engineer and reference NZS 3101:2006 and NZBC Clause B1.

Imagine a warehouse that can handle heavy machinery, survive an earthquake, and still look sleek. That’s the promise of Type5 building construction - a system built to bear massive loads while meeting strict safety standards.

Quick Takeaways

- Type5 uses reinforced concrete load‑bearing walls as the primary structural system.

- It satisfies the New Zealand Building Code (NZBC) requirements for fire rating and seismic performance.

- Ideal for commercial warehouses, factories, and multi‑storey office blocks.

- Design focuses on simplicity, durability, and cost‑effective construction.

Definition and Core Concept

Type 5 building construction is a construction classification where the structural integrity relies primarily on reinforced concrete load‑bearing walls to support floors, roofs, and lateral forces. Unlike steel‑frame or timber systems, the walls themselves carry the vertical loads, reducing the need for separate columns in many layouts.

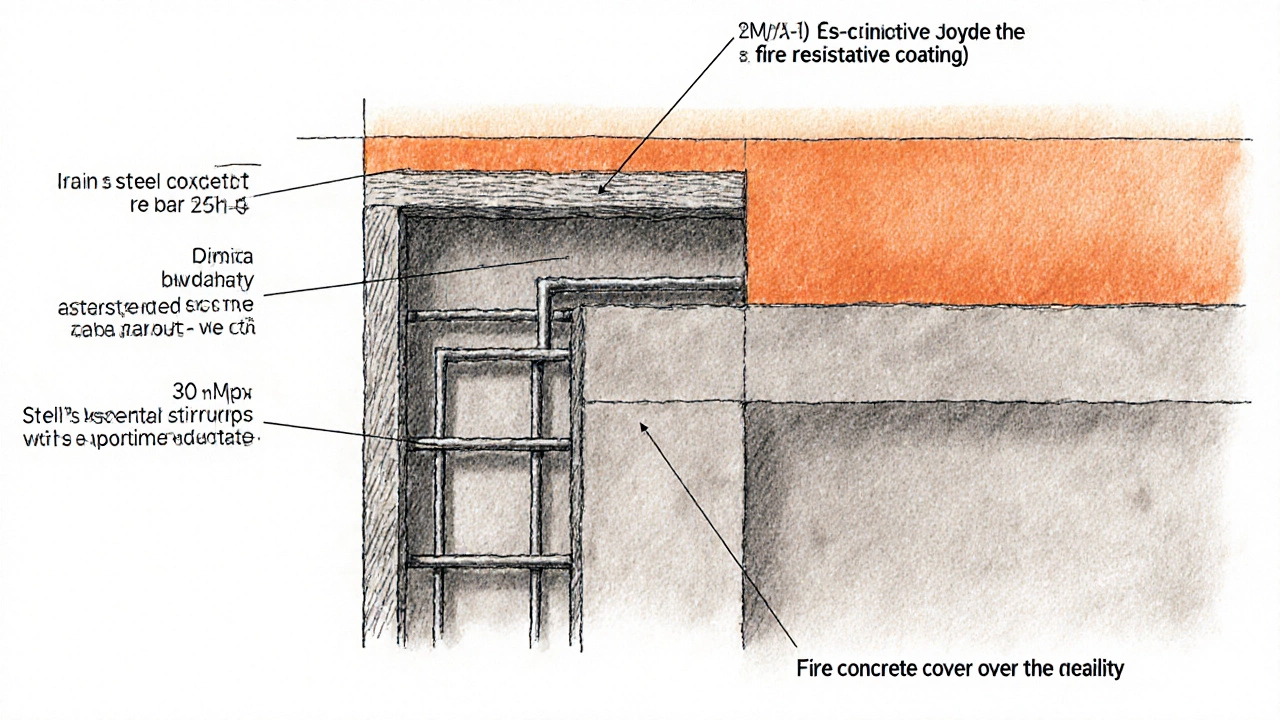

Key Components

Four elements define a Type5 system:

- Reinforced concrete provides the compressive strength needed for heavy loads. The concrete mix typically follows NZS 3101 standards, achieving a 28‑day compressive strength of 30MPa or higher.

- Load‑bearing walls are poured in situ or cast as precast panels, forming the building’s skeleton.

- Steel reinforcement (rebar) is embedded within the concrete to resist tensile forces, especially during seismic events.

- Fire rating is achieved by selecting concrete mixes and protective coatings that meet the minimum 1‑hour fire resistance required by the NZBC.

How It Satisfies Building Codes

The New Zealand Building Code (NZBC) mandates three performance criteria for commercial structures: structural stability, fire safety, and durability. Type5 addresses each:

- Structural stability: The mass of reinforced concrete walls provides inherent damping, helping the building absorb seismic energy. NZBC Clause B1 requires a design earthquake of up to 1.2g in many regions; engineers calculate base shear using the New Zealand Standard (NZS) 3101:2006.

- Fire safety: Concrete inherently resists fire. By specifying a 30‑mm fire‑resistive coating, the system complies with Clause C2 - a minimum 1‑hour fire resistance for walls separating different fire zones.

- Durability: Proper concrete cover (typically 25mm over rebar) ensures resistance to corrosion in coastal Auckland climates, aligning with Clause D1’s durability expectations.

Typical Applications

Because of its load‑bearing nature, Type5 shines in environments where floor loads exceed 5kN/m². Common projects include:

- Distribution warehouses that store pallets of up to 2t each.

- Manufacturing plants with heavy machinery foundations.

- Multi‑storey office blocks where open‑plan layouts benefit from fewer internal columns.

- Retail big‑box stores that require large, unobstructed floor plates.

Advantages and Limitations

Every system has pros and cons. Here’s a balanced view:

| Benefit | Why It Matters |

|---|---|

| High load capacity | Handles heavy equipment without extra columns. |

| Fire resistance | Concrete’s inherent fire‑proof nature reduces additional protection costs. |

| Seismic performance | Mass and ductility of reinforced concrete improve post‑earthquake stability. |

| Low maintenance | Concrete does not rot or warp, lowering long‑term upkeep. |

On the flip side, Type5 can be:

- Heavier, leading to larger foundations and higher transport costs for materials.

- Longer construction cycles if poured on‑site; precast panels can offset this but add logistics complexity.

- Less adaptable to future vertical expansions compared with steel frames.

Design and Construction Process

From concept to handover, a typical Type5 project follows these steps:

- Site assessment: Geotechnical surveys determine bearing capacity. In Auckland, many sites require pile foundations to support the extra dead load.

- Concept design: Architects layout the floor plan to align walls with load paths, reducing unnecessary columns.

- Structural analysis: Engineers model the walls in software like ETABS, applying NZS 3101 loads and seismic coefficients.

- Detailing: Rebar schedules are produced, specifying bar sizes (typically 16mm-25mm) and spacing.

- Formwork & pouring: On‑site formwork or precast panels are installed; concrete is placed, vibrated, and cured for at least 7days.

- Inspection & certification: Local council inspectors verify compliance with the NZBC before the building receives its code compliance certificate.

Comparison with Other Construction Types

| Type | Primary Structure | Typical Load Capacity | Fire Rating | Seismic Suitability |

|---|---|---|---|---|

| Type1 | Timber frame | Up to 2kN/m² | Requires cladding | Good with bracing |

| Type2 | Steel frame | 2‑4kN/m² | Fire‑protected steel | Excellent |

| Type3 | Reinforced concrete frame | 4‑6kN/m² | Concrete fire rating | Very good |

| Type4 | Hybrid (steel & concrete) | 5‑7kN/m² | Combined systems | High |

| Type5 | Reinforced concrete load‑bearing walls | >5kN/m² (commonly 8‑12kN/m²) | Inherent 1‑hour+ | Excellent with proper detailing |

Choosing the right type depends on load requirements, budget, and local code constraints. For heavy‑load commercial projects in seismic zones, Type5 often offers the best blend of strength and fire safety.

Quick Checklist for Project Managers

- Confirm the building’s design earthquake level (NZS 3101).

- Verify concrete mix meets ≥30MPa compressive strength.

- Ensure rebar cover meets corrosion protection standards for coastal sites.

- Plan for fire‑resistive coating if walls separate different fire zones.

- Schedule early council inspection to avoid certification delays.

Frequently Asked Questions

What distinguishes Type5 from a regular reinforced concrete frame?

In a Type5 system the walls themselves carry the vertical load, eliminating many interior columns. A regular concrete frame relies on a skeleton of beams and columns with infill walls.

Can Type5 be used for residential buildings?

It’s possible but uncommon. Residential codes often favor timber or light‑weight frames for cost efficiency. Type5 shines where high floor loads or fire rating are critical.

How does seismic design differ for Type5 walls?

Engineers increase transverse reinforcement (stirrups) and use higher‑grade concrete to improve ductility. The wall thickness is also optimized to balance stiffness and flexibility.

What are the cost implications compared to steel frame?

Material costs are similar, but labor can be higher for on‑site concrete pours. However, the reduced need for steel columns can offset that, especially in large floor plates.

Is Type5 suitable for quick construction timelines?

Using precast wall panels can accelerate the schedule dramatically, cutting on‑site curing time. Pure cast‑in‑place walls will extend the timeline.

Written by Fletcher Abernathy

View all posts by: Fletcher Abernathy